Process Introduction

Introducing the R & D process of Bowon Metal Co., Ltd., preparing for the future.

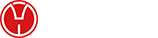

FORMER Flowchart Simulation

Bowon Metal

Process Introduction

- 01 Raw Material

- CHQ wire rods such as carbon steel and alloy steel are purchased from steel companies and used after import inspection.

- 02 Forging

- Process that can shape the shape of the product from 2 to 6 steps through plastic processing such as cutting, extrusion and forging

- 03 Form Rolling

- Process of forming thread by using mold on forged product

- 04 Heat Treatment

- Process to give strength, hardness, wear resistance, processability, impact resistance, etc. for carburizing, unwinding, soaking, high frequency, and quality (Q&T) treatment

- 05 Surface Treatment

- Process to improve wear resistance and heat resistance of metal with phosphate coating and zinc plating on product surface and to prevent corrosion of product

- 06 Packing

- The process of preparing for shipment in the shortest delivery time based on customer requirements

- 07 Shipment

- Deliver the finished product on time according to customer requirements

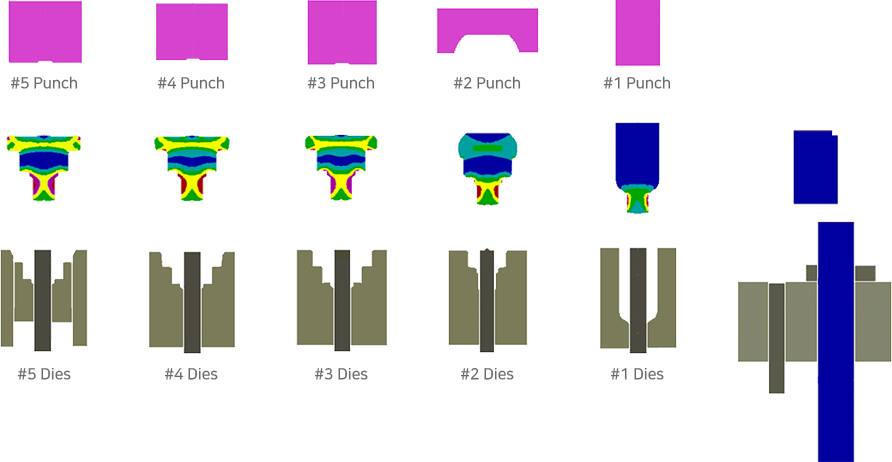

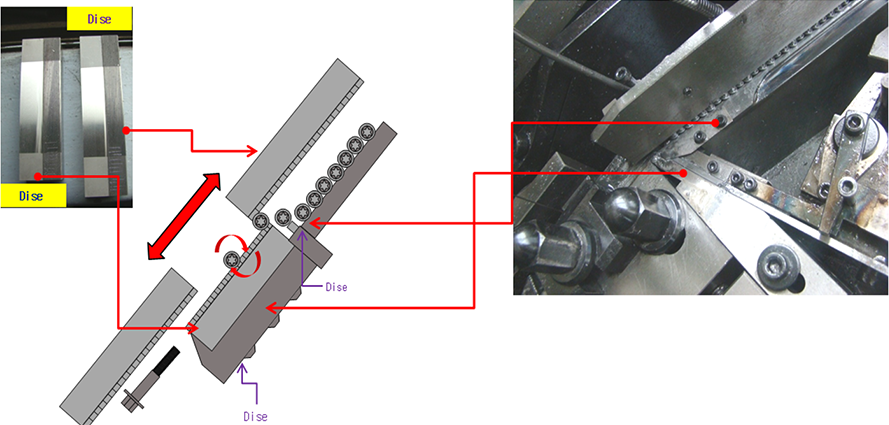

FORMER MACHINE Performance

1st and 6th stages of 1st stroke. Except for initial setting, one product comes out for each turn of the crankshaft. Even products with relatively high monotonic pressure and complex shapes can be molded at a time, resulting in reduced production LEAD TIME and higher facility rotation rate, which greatly improves CAPA.

In addition, material cutting surfaces and products are moved to trans tongs, which are very useful for geometries.

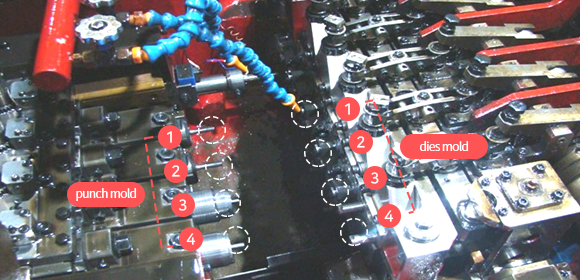

For the current installation, the part TYPE, rather than the regular bolt foam, allows rotating from a die mold to punch molding, making it very useful for relatively short BUSHING and piercing products.